COMPUTER AND DESIGN LABORATORY

The Highway and Asphalt Laboratory was established to train students to design asphalt pavement mixes and testing the mixes for ensuring conformance to design specifications. In addition, the laboratory was found for research purpose also at postgraduate level to deeply study in engineering properties of asphaltic concrete and highway materials. The Highway and Asphlat Laboratory is located at second floor of new civil laboratories building.

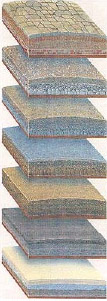

The laboratory is suitably equipped with conventional bituminous materials testing equipment for determining the consistency of asphalt cements. These include controlled temperature baths, viscometer thermometers, and pressure regulators to perform standard test methods for kinematic and absolute viscosity, penetration resistance, ductility, softening point (Ring and Ball Apparatus), flash and fire point (Cleveland Open Cup), float test and fractional distillation. Pycnometers are also available for determining specific gravity for weight and volume corrections. For emulsions, there is also available the general equipment for testing the composition, consistency and stability of emulsified asphalts.

We have conventional asphalt testing equipments/instruments for laborary testing and on-site testing purpose. These including the detemining the asphalt (bitumen)/aggregate softening point, max. Bulk/apparent specific gravity, absorption, contents & properties. The instruments can also measure deformation, fatigue cracking, moisture susceptibility, static/dynamic tension-compression tests, stability, flow time, viscosity, compaction, breaking point, penetration, elongation before failure, etc. All equipment and apparatus in the lab is calibrated and used according to ASTM and AASHTO Standards and all tests are performed according to ASTM, AASHTO, AI, FHWA, and NCAT Test Specifications.

For testing the strength and resistance to plastic deformation of compacted bituminous mixtures specimens or flexible pavement cores, the laboratory is equipped with a Marshall Stability and Flow device. Supporting equipment for this test method such as mixers, ovens, automated Marshall and kneading compactors, noise reduction chamber, mechanical shakers and sieves, compaction molds, and analytical and mechanical balances, are also available. Other supporting accessories are available to perform the maximum specific gravity test method of uncompacted bituminous mixtures (Rice method). The overall condition of the equipment to meet instructional requirements at the undergraduate and postgraduate level is very good.

The highway and asphalt laboratory was found for basic study and research purpose at postgraduate level also to deeply study in engineering properties of asphaltic concrete and new highway materials.